10-15 MW PV Solar Panel Production Line - Classic

Our state-of-the-art 10-15 MW PV solar panel production line, designed by J.v.G. technology GmbH, offers flexibility and adaptability to meet diverse market demands.

We provide comprehensive services, including factory layout design, building engineering, process and plant technology, project management, and engineering assistance. Our 10-15 MW production line includes a selection of top-notch machines for efficient manufacturing.

With our industry leadership, experienced team, commitment to harnessing solar potential, and proven trustworthiness, we are your reliable partner for all solar panel production needs.

10-15 MW PV Solar Panel Production Line - Classic: Introduction

Solar panel production is the state-of-the-art manufacturing system, thoughtfully designed by J. v. G. technology GmbH, is engineered with flexibility in mind, enabling efficient changes in the manufacturing process. This flexibility is pivotal for producing components tailored to different solar module systems and staying in sync with the dynamic demands of the market.

The core of this solar panel modules production line's capability lies in its ability to provide an array of services. This ensures that customers can harness the full potential of photovoltaic technology while seamlessly integrating it into their projects. J. v. G. technology GmbH, a global leader in photovoltaic system design and manufacturing, has crafted a comprehensive set of services to empower its clients in developing and implementing their solar PV systems. To explore these services further, simply submit the form on the right to receive more detailed information.

We Include the Following Services

J. v. G. technology GmbH is a global leader in designing and manufacturing photovoltaic (PV) systems. J.v.G. technology GmbH offers various services to support its customers in developing and implementing their PV systems. Submit the form on the right to receive more information.

Factory Layout

The blueprint for an efficient and effective 10-15 MW solar manufacturing line begins with a meticulous factory layout. The individual 3D CAD drawings of the complete line, encompassing all necessary support systems like power, pneumatic, and exhaust, play a pivotal role in the design and construction process. These detailed designs enable cost-effective production line creation, reducing both time and resource overheads, and ensuring seamless integration with your existing operations.

Buildings

A pivotal aspect of a successful solar panel production line is the careful planning of the entire factory building. These technologies involves designing not just the production area but also the warehouse and office spaces. The strategic selection of locations for these crucial elements, along with a well-thought-out building layout, ensures smooth operations, streamlining your entire manufacturing process.

Building Engineering

For the safe and efficient operation of a solar photovoltaic production line, a detailed plan encompassing facility and environmental requirements is imperative. This plan goes beyond equipment selection and encompasses facility layout and the overall environment within which the production line operates. Attention to these details is paramount in maintaining both the productivity and sustainability of the photovoltaics module manufacturing.

Process and Plant Technology:

Bringing a 10-15 MW PV production line to life involves more than just machinery. It necessitates a full turnkey service that includes training, process development, and production ramp-up. Comprehensive staff training in line operation and maintenance is critical to ensuring the solar cells production line's longevity. The development and implementation of the manufacturing process, combined with a meticulous start-up strategy, all fall under the umbrella of this service. This approach aims to not only get the production line up and running but to keep it running efficiently for years to come.

Project Management and Controlling

J. v. G. technology GmbH's commitment to your project extends from the initial machine orders through to production commencement. This hands-on project management is invaluable in helping customers select the right machines for their PV manufacturing line. It also ensures a seamless installation process and effective commissioning, thus avoiding any potential hiccups that might delay production.

Comprehensive Engineering Services

Assistance in all steps of the project, like technical data for panel datasheet, purchasing of material, and other related tasks. This assistance includes helping customers select the appropriate components and materials for their MW PV production line, such as the type of solar panel, cables, and other components.

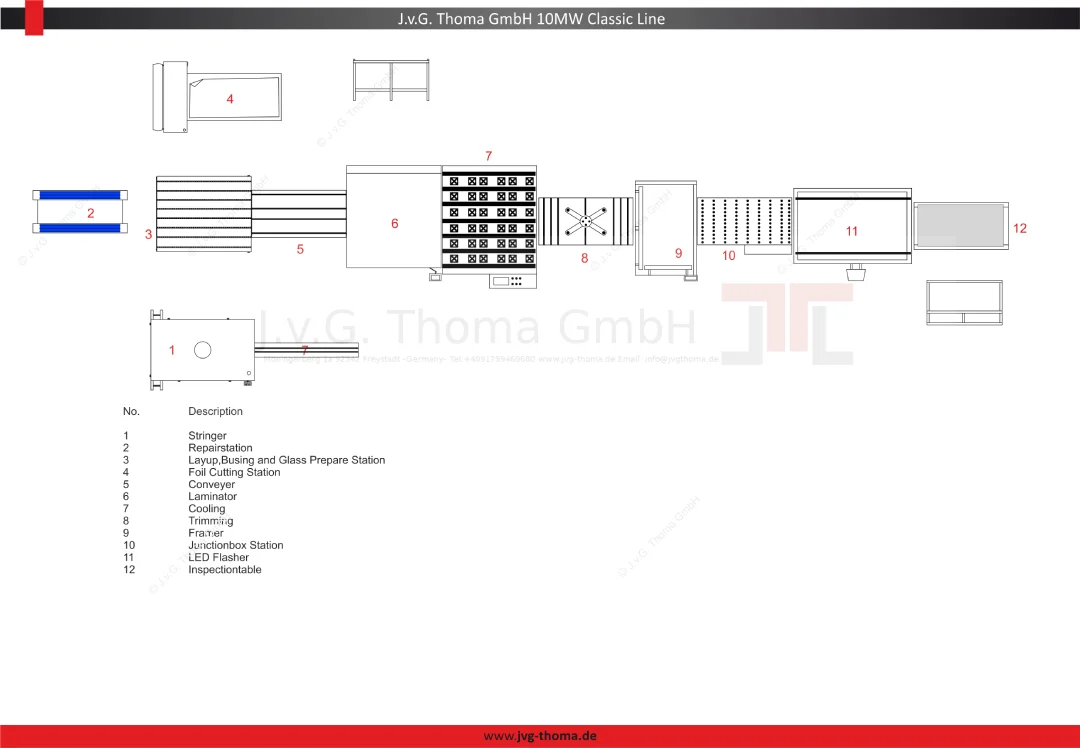

10-15 MW PV Solar Panel Production Line - Classic includes the following machines:

In addition to these critical services, J. v. G. technology GmbH's 10-15 MW solar panel production Line - Classic includes a selection of top-notch machines that form the backbone of the entire system. These machines are designed to ensure smooth and efficient manufacturing, making it easier for your team to produce high-quality photovoltaic components. The list of machines comprises:

Why You Should Hire J. v. G. technology GmbH for Engineering Services

Industry Leadership and Expertise

J. v. G. technology GmbH has established itself as a leader in the solar panel production industry, offering a wide array of machines and a reservoir of knowledge and expertise. When you engage with J. v. G. technology GmbH, you're partnering with an industry standard in PV modules, ensuring access to cutting-edge technology and innovative solutions. As a renewable energy leader, they are committed to driving growth and development by providing top-tier services.

Experienced and Highly Qualified Team

The backbone of J. v. G. technology GmbH is its team of highly qualified experts, each boasting years of experience in the solar industry. This team collaborates closely with customers to develop customized solutions tailored to their unique requirements. This personalized approach ensures that your solar projects are in the hands of dedicated and knowledgeable professionals who understand the intricacies of the solar industry.

Harnessing Solar Potential

Solar energy is undeniably a driving force in the future of electricity production. J. v. G. technology GmbH is passionate about unlocking the full potential of solar power and helping their customers do the same. With their support, you can embark on a journey to harness the sun's energy and contribute to a more sustainable world.

Comprehensive Services

J. v. G. technology GmbH's offerings go beyond just selling machines. They provide services that encompass every aspect of your solar panel production journey, from initial design to the installation of turn-key silicon and cell production systems. Their commitment doesn't end once your production begins; they'll stand by your side with advice and support. Furthermore, their ability to purchase and sell used solar components extends their range of services, making them a one-stop solution for all your solar needs.

Proven Trustworthiness

The trust placed in J. v. G. technology GmbH by numerous renowned enterprises in Europe, the Americas, and Asia speaks volumes about their reliability and competence. Their extensive list of references attests to their successful collaborations and impeccable service. If you want to witness firsthand what they can do for you, they're more than willing to arrange a visit to their solar panel production facilities, allowing you to see their capabilities up close.